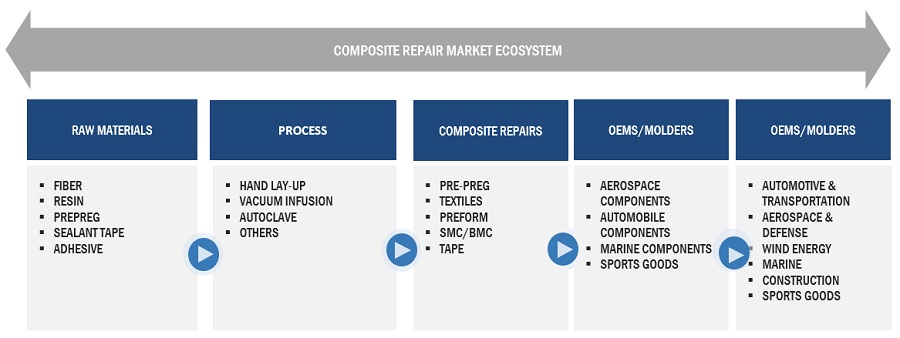

Composite Repair Market by Type (Structural, Semi-Structural, Cosmetic), Process (Hand Lay-Up, Vacuum Infusion, Autoclave), End-Use Industry (Aerospace & Defense, Wind Energy, Automotive & Transportation, Marine), and Region - Global Forecast to 2028

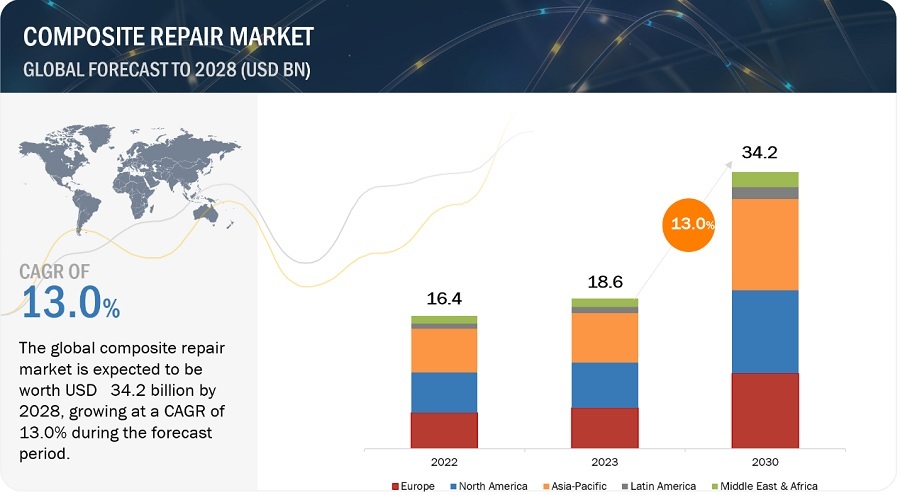

The composite repair market is projected to grow from USD 18.6 billion in 2023 and is projected to reach USD 34.2 billion by 2028, at a CAGR of 13.0%. Over the world, the composite repair market is expanding significantly, and during the forecast period, a similar trend is anticipated. The demand for composite repair has been driven by several factors, including the increasing investment in rehabilitating old structures, and cost saving associated with composite structure repair. The major applications of composite repair include aerospace & defense, wind energy, automotive & transportation, marine, construction, pipes & tanks, and others.

In the aerospace industry, with a significant increase in the application of fiber-reinforced composites across the aircraft parts over the past decade, the repairs market is expected to grow significantly. The composite repair requirement will be driven by the new-generation commercial passenger aircraft, including 787 Dreamliner and A350; these aircraft account for 50% and 53% composites by weight, respectively. Although, these aircraft save 20%–30% of the maintenance cost, the damage due to lightning, collision with bird or any other object will need composite repair.

In the wind energy industry, composite wind turbine blades have an expected service life of 15–20 years. Most of the rotor blades carry 1–2 years of post-installation warranty. So, still, there are 17–18 years outside the warranty period, which require proper maintenance and repair. Without proper repair and maintenance, the efficiency diminishes with every defect on the surface and this results in a reduction in power production. The European wind energy market is more mature than the U.S. and the inspection is much regular in Europe. However, the operators in the U.S. are paying importance to regular blade maintenance.

Attractive Opportunities in Composite repair Market Trends

To know about the assumptions considered for the study, Request for Free Sample Report

Composite repair Market Dynamics

Driver: cost saving associated with composite structure repair

Composite parts replacement is very costly. Thus, repair is preferred until the damage is non-repairable or a potential risk is associated with it. Composite repair can save up to 60% of the cost than replacement depending upon the end-use industry, type of repair, and damage.

For example, composite repair saved one-sixth of the cost as compared to the replacement in Carter Country Bridge over the Little Sandy River, which was first decided to be replaced and could cost USD 600,000. But, through repair it was completed only in USD 105,000. So, in the coming years with the ageing aircraft, bridges, and wind turbines composite repair will be adopted significantly.

Restraint: low penetration of composites in end-use industries in the least developed countries

In least developed countries of South America and Africa, the use of conventional material such as steel, aluminum, and wood are comparatively more than the composites. The resistance to change from conventional to advanced material is restricting the growing use of composites. The switching cost from conventional materials to composites is also higher. As a result of these challenges, the penetration of composites in the least developed countries of Africa and South America is still very low. This is acting as the restraint for the composite repairs market.

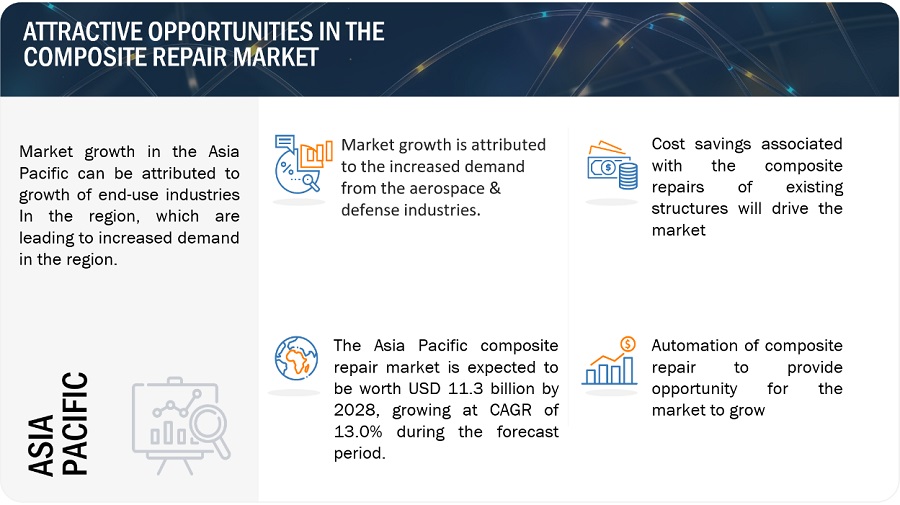

Opportunity: Automation of composite repair

Manual composite repair is time-consuming and incur higher cost. Automated repair saves 60% of the time than manual composite repair. This also saves cost as well as the risk of human error. With the increasing usage of composites in components from flaps, engine nacelles, fairings, vertical tail, to the entire forward wing structure and fuselage, the repair will be more difficult in the future. The airline and MRO companies have to gear up to meet the increasing composite repair demands. Currently, several automated repair technologies are under development including a fairly small mobile system by Airbus Group Innovations (Germany), the Inspection and Repair Preparation Cell (IRPC) (U.S.), and a system using resin infusion by the German Aerospace Center (Germany). Airbus Group Innovations (Germany) uses robotic arm to perform digital scanning, ultrasonic testing, milling to remove damage and automated tape laying to create patch repair, and then automate patch application. GKN Aerospace was involved in developing automated laser technology to improved, cost-effective composite structure repair, while consuming one-third time and saving 60% cost.

BCT GmbH (Germany) is also introduced automatic scarfing in 2013 to reduce machining time and to improve the quality of the repair preparations. A prototype mobile robot was also built and tested on actual aircraft. This demonstrated the ability to complete bonded composite repairs. on carbon fiber-reinforced plastic (CFRP) structure such as 787 and A350 XWB fuselages and wings.

Challenge: Skilled labor shortage

The lack of skilled composite repair technicians is one of the major challenges for the composite repairs market. In several countries, absence of proper and recognized training standards is also posing challenges for the market. As the use of composites in end-use industries will be aging, there will be significant demand for composite repair personnel. It is crucial to complete scheduled and effective repair of damages to avoid any project downtime and financial loss.

At the current situation, the availability or supply of trained personnel is disproportional to the growing demands. This may cause a long-term skill shortage and consequently can impact the quality and availability of inspection and repair.

It requires training, practice, and experience to become proficient in composite repair. The market lacks in the internationally recognized standards for composite repair. To avoid this, end-users are developing and offering training specific to their types of repair.

Market Ecosystem-

Cosmetic type of composite repair products to be the fastest growing market by 2028, in terms of value.

The cosmetic repair segment is expected to witness the highest CAGR in the next five to ten years with the significant increase in the usage of composites in automobiles in order to increase the fuel efficiency. If during inspection it is found that the damage is minor and it has not affected the structural integrity of the component, then a cosmetic repair is carried out to decorate and protect the surface. In cosmetic repair, reinforcing material is not used, rather non-structural filler is used to protect the surface until a more permanent repair is being carried out. Through cosmetic repair the structure does not regain any strength, therefore, it is used only where strength is least important. High shrinkage may cause the cosmetic repairs to start cracking after a short period of time in operation. In general, the repairs done to motors, cars, and other vehicles constructed from composite materials are cosmetic rather than structural as if the body panels are damaged they cannot be repaired through cosmetic repair process, the damaged part has to be replaced.

Autoclave to be the fastest growing segment in the composite repair market, in terms of value.

Autoclave is a pressure vessel, which provides curing condition to the composite where the application of vacuum, pressure, heat, and cure temperature are controlled. The high pressure helps to mold the thicker sections of complex structures. This process takes long cure cycle as large autoclave mass takes long time to heat and cool down. An autoclave applies both heat and pressure to the workload placed inside of it.

Most of the aircraft parts are repaired by autoclave process. Autoclaves used for composite bonding in the aerospace, military, and other high-performance industries must be built with extra care with attention to detail. Autoclave is a costlier process as compared to hand lay-up and vacuum infusion processes. It offers high quality of repair. Thus, it is only affordable in repair of components where high performance is crucial, such as aerospace parts.

Automotive & Transportation end-use industry segment to be the fastest growing the composite repair market, in terms of value.

The use of composites in the global automotive industry is still small. Carbon fiber-reinforced plastics are limited to racing cars, supercars, and high-end luxury vehicles. However, in order to meet the recent fuel economy and emission standards, the demand for carbon fiber composites is expected to grow at a significant rate. Further, the economies of scale will make it more affordable. Currently, in high-end cars, carbon fiber-reinforced plastics are used in body panels, hoods, deck, roofs, fenders, and door panels. In case of damage, they are either replaced or removed as it associates a little incentive to repair despite their high cost. But, as the penetration of composites increases in structural components of chassis, new repair strategies are expected to emerge in the coming years.

The automotive industry is expected to adopt the repair techniques used in aerospace.

In automotive composite repairs, use of two-part epoxy adhesive is most common. For smaller repairs, single-unit adhesive applicator with two chambers loaded with adhesive resin and curing agent is used. For severe damage, the entire body panel or subpanels are removed, and a replacement piece is attached with the help of adhesive. Other than adhesive repair, fusion technique is also used whereby heating the damaged area minor damages are repaired by resin flowing back together.

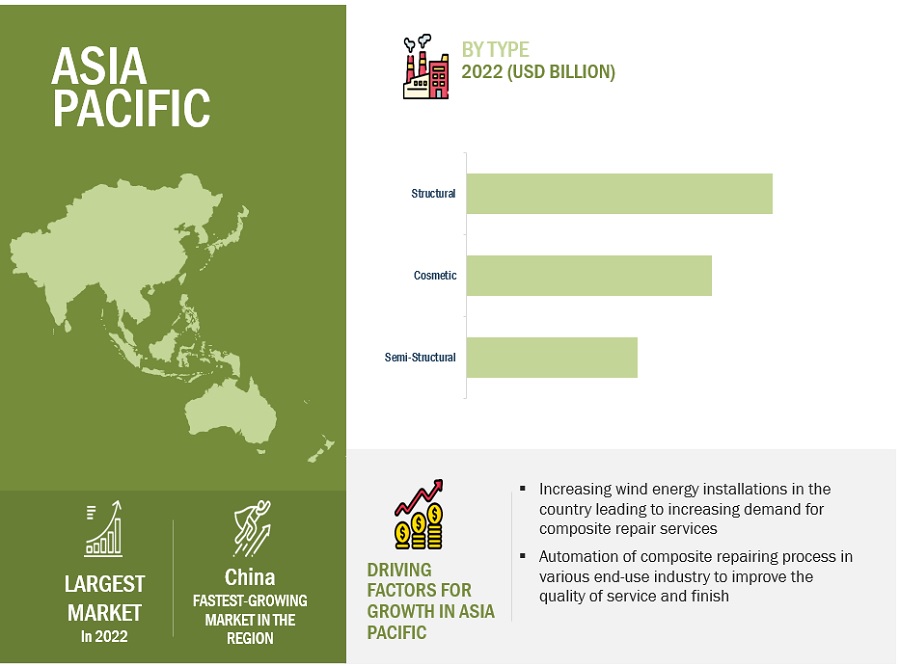

Asia Pacific held the largest market share in the composite repair market.

Asia-Pacific accounted for the largest market share of 32.9% in the global composite repairs market and is projected to lead during the forecast period owing to the largest existing wind energy capacity installations in China, Japan, India, and Australia. The aerospace composite repairs market also has significant opportunities as plenty of aircraft orders are being placed by airlines in the region. In Asia-Pacific, China, Japan, India Australia & New Zealand, South Korea, and Thailand are the key countries in the composite repairs market. Asia-Pacific is the fastest growing composite repairs market, which is projected to register a CAGR of 13.1% between 2023 and 2028. The remarkable growth of the wind energy industry in the Asia-Pacific has driven the composites and thereby the composite repairs market in this region.

To know about the assumptions considered for the study, download the pdf brochure

Key Market Players

The composite repair market is dominated by a few globally established players such as Lufthansa Technik AG (Germany), Air France KLM E&M (France), and HAECO (U.S.), UpWind Solution (U.S.), Total Wind Group A/S (Denmark), and Technical Wind Services (Scotland), Citadel Technologies (U.S.), Milliken Infrastructure (U.S.), and T.D. Williamson (U.S.), West Systems (U.S.) and WR composites (U.K.), Fibrwraps (U.S.) and Concrete Repairs Ltd. (U.K.), among others, are the key manufacturers that secured major contracts in the last few years. Major focus was given to the contracts and new product development due to the changing requirements across the world.

These companies are pursuing a variety of inorganic and organic strategies in order to gain a foothold in the composite repair market. The research includes a detailed competitive analysis of these key players in the composite repair market, including company profiles, recent developments, and key market strategies.

Get online access to the report on the World's First Market Intelligence Cloud

- Easy to Download Historical Data & Forecast Numbers

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

Request Sample Scope of the Report

Get online access to the report on the World's First Market Intelligence Cloud

- Easy to Download Historical Data & Forecast Numbers

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

|

Report Metric |

Details |

|

Market size available for years |

2020 - 2028 |

|

Base year considered |

2022 |

|

Forecast period |

2023 – 2028 |

|

Units considered |

Value (USD billion/million) |

|

Segments Covered |

By Type, By Process, By End-Use Industries, Region |

|

Geographies covered |

Europe, North America, Asia Pacific, Latin America, the Middle East, and Africa |

|

Companies covered |

Lufthansa Technik AG (Germany), Air France KLM E&M (France), and HAECO (U.S.), UpWind Solution (U.S.), Total Wind Group A/S (Denmark), and Technical Wind Services (Scotland), . Citadel Technologies (U.S.), Milliken Infrastructure (U.S.), and T.D. Williamson (U.S.), West Systems (U.S.) and WR composites (U.K.), Fibrwraps (U.S.) and Concrete Repairs Ltd. (U.K.). |

The study categorizes the composite repair market based on Glass type, Product type, Application, and Region.

By Type:

- Structural

- Semi-Structural

- Cosmetic

By Process:

- Hand Lay-Up

- Vacuum Infusion

- Autoclave

- Others

By End-User:

- Aerospace & Defense

- Wind Energy

- Automtoive & Transportation

- Marine

- Construction

- Pipes & Tanks

- Others

By Region:

- North America

- Asia Pacific

- Europe

- Latin America

- Middle East & Africa

Recent Developments

- In March 2023, AFKLM E&M and Spirit AeroSystems entered an agreement for the repair and overhaul of composite components for Spirit's commercial aircraft. The agreement includes a long-term commitment from Spirit, and it will allow Air France-KLM E&M to expand its capacity for composite repair and overhaul.

- In November 2022, TWS signed a new deal with Innogy Renewables to provide operations and maintenance services for the East Anglia One offshore wind farm. The deal is worth USD 50.26 million.

- In June 2022, UpWind Solutions partnered with GE Renewable Energy to provide asset management services for GE Renewable Energy's wind turbines.

- In March 2022, Total Wind Group signed a deal with Iberdrola to provide operations and maintenance services for the Wikinger offshore wind farm in the Baltic Sea. The deal is for a period of 15 years and is worth an estimated USD 1 billion.

Frequently Asked Questions (FAQ):

What are the factors influencing the growth of the composite repair market?

Automation of composite repair.

Which is the largest country-level market for composite repair market?

China is the largest composite repair market due to high demand from well-established end-use industries.

What are the challenges in the composite repair market?

Lack of standardization on materials and testing in the composite repair market.

Which type of composite repair type holds the largest market share?

structural type hold the largest share in terms of value, in the composite repair market.

How is the composite repair market aligned?

The market is growing at a faster pace. It is a potential market and many service providers are undertaking business strategies to expand their business.

Who are the major manufacturers?

Lufthansa Technik AG (Germany), Air France KLM E&M (France), and HAECO (U.S.), UpWind Solution (U.S.), Total Wind Group A/S (Denmark), and Technical Wind Services (Scotland), . Citadel Technologies (U.S.), Milliken Infrastructure (U.S.), and T.D. Williamson (U.S.), West Systems (U.S.) and WR composites (U.K.), Fibrwraps (U.S.) and Concrete Repairs Ltd. (U.K.).

What is the biggest restraint in the composite repair market?

Introduction of self-healing composites is one of the biggest restraining factors for the market growth. .

To speak to our analyst for a discussion on the above findings, click Speak to Analyst

The study involves two major activities in estimating the current size of the composite repair market. Exhaustive secondary research was done to collect information on the market, the peer market, and the parent market. The next step was to validate these findings, assumptions, and sizing with industry experts across the value chain through primary research. Both the top-down and bottom-up approaches were employed to estimate the total market size. After that, market breakdown and data triangulation procedures were used to determine the extent of market segments and sub-segments.

Secondary Research

In the secondary research process, information has been sourced from annual reports, press releases & investor presentations of companies; white papers; certified publications; trade directories; articles from recognized authors; and databases. Secondary research has been used to obtain critical information about the industry's value chain, the total pool of key players, market classification & segmentation according to industry trends to the bottom-most level, and regional markets. These have also been utilized to obtain information about the key developments from a market-oriented perspective. Secondary research was mainly conducted to obtain key information about the supply chain of the industry, the total pool of players, market classification and segmentation according to industry trends to the bottom-most level, regional markets, and key developments from both market- and technology-oriented perspectives.

Primary Research

The stakeholders in the value chain of the composite repair market include raw material suppliers, processors, end-product manufacturers, and end users. Various primary sources from the supply and demand sides of the market have been interviewed to obtain qualitative and quantitative information. Primary sources from the demand side include key opinion leaders from various end-use industries in the composite repair market. Primary sources from the supply side include experts from companies involved in the composite repair.

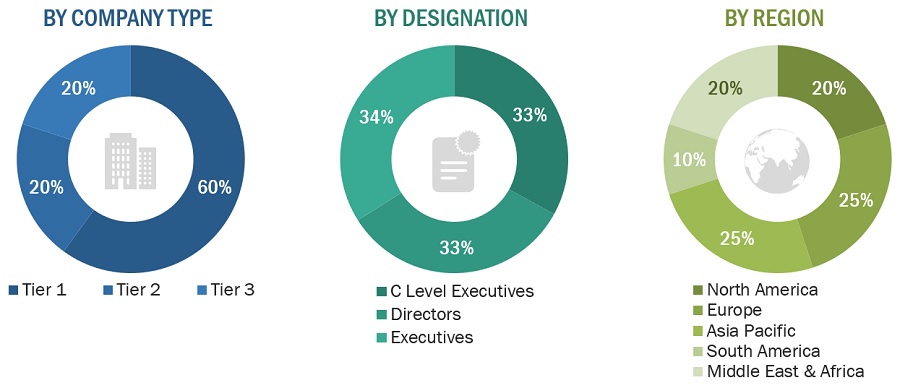

The Breakup of Primary Research

To know about the assumptions considered for the study, download the pdf brochure

Market Size Estimation

The research methodology used to estimate the size of the composite repair market includes the following details. The market sizing of the market was undertaken from the demand side. The market was upsized based on procurements and modernizations in composite repair in different applications of the composite repair industry at a regional level. Such procurements provide information on the demand aspects of the composite repair industry for each application. For each application, all possible segments of the composite repair market were integrated and mapped.

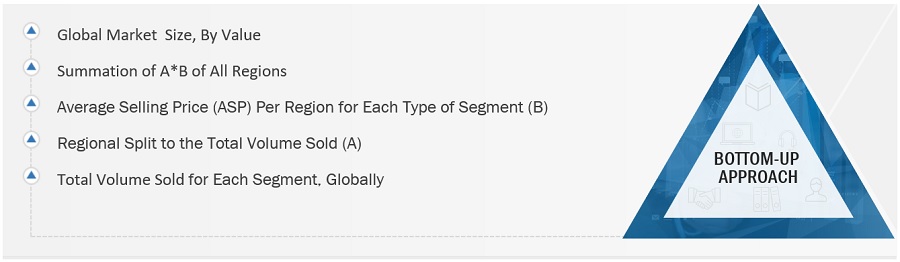

Composite repair Market Size: Botton Up Approach

To know about the assumptions considered for the study, Request for Free Sample Report

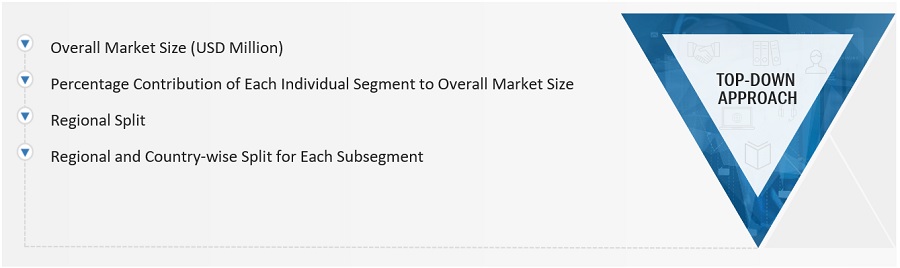

Composite repair Market Size: Top Down Approach

Data Triangulation

After arriving at the overall size from the market size estimation process explained above, the total market was split into several segments and subsegments. The data triangulation and market breakdown procedures explained below were implemented, wherever applicable, to complete the overall market engineering process and arrive at the exact statistics for various market segments and subsegments. The data was triangulated by studying various factors and trends from the demand and supply sides. Along with this, the market size was validated using both the top-down and bottom-up approaches.

Market Definition

Fiber-reinforced composites are used in end-use industries including aerospace & defense, wind energy, automotive & transportation, marine, construction, pipe & tank, electrical & electronics, and sporting goods. However, due to several reasons such as lightning, collision, bird strike, erosion, corrosion, or manufacturing defects, the composite structure gets damaged. As composite parts replacement is costlier, composite repair is performed on disbands or delamination, holes or punctures, cracks, and other damages to bring back the part to its previous working condition.

Key Stakeholders

- Senior Management

- End User

- Finance/Procurement Department

- R&D Department

Report Objectives

- To analyze and forecast the global composite repair market size, in terms of volume and value

- To provide detailed information about the key factors (drivers, restraints, opportunities, and challenges) influencing the growth of the market

- To analyze the market segmentation and forecast the market size based on type, process, and end-use industry.

- To analyze and forecast the market size based on five main regions, namely, Asia Pacific (APAC), Europe, North America, Middle East & Africa (MEA), and Latin America.

- To analyze the market with respect to individual growth trends, prospects, and contribution of submarkets to the total market

- To analyze the market opportunities and the competitive landscape for stakeholders and market leaders

- To analyze competitive developments such as expansions, partnership, agreement, new product/technology launch, joint venture, contract, and merger & acquisition in the market

- To profile key players and comprehensively analyze their market share and core competencies

Available Customizations

MarketsandMarkets offers following customizations for this market report:

- Additional country-level analysis of the composite repair market

Product Analysis

- Product matrix, which provides a detailed comparison of the product portfolio of each company's market

Growth opportunities and latent adjacency in Composite Repair Market